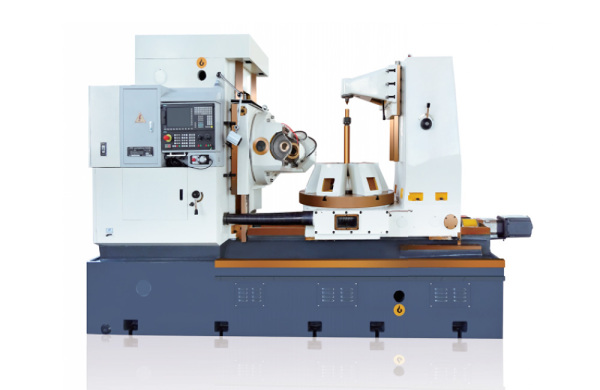

CG series cylindrical surface grinder is suitable for grinding outer surface of cylinder and taper.

UCG series cylindrical surface grinder is suitable for grinding outer/inner surface of cylinder and taper.

The longitudinal movement of the worktable is driven by hydraulic or by handwheel. The worktable can to a certain degree so as to be suitable forgrinding taper.

The wheelhead cross feed is driven by hydraulic, which realizes automatic periodical feed and rapid feed and ropid feed. It can also do rough and fine feed through handwheel.

The worktable and wheelhead guide way of the CG50, UCG50 series adopt hydrostatic lubrication, its movement onlow speed is smooth.

The spindle of CG50 and UCG50 series is supported by hydrostatic and hydrodynamic bearings of high rigidity, it makes the spindle have high rotary accuracy and perfect rigidity.

The wheelhead of CG50 adopts double-speed motor and its speed can be changed by changing the position of belt. The wheelhead of the universal type (UCG50) adopts inverter motor to realize stepless speed changing. The wheelhead spindle of the universal type (UCG50) adopts sliding bearing structure.

The clearance of the realize stepless speed changing. The wheelhead spindle of the universal for the grinding Use center of chuck The workhead of the universal type can be rotate to any position within its conterclock direction 90° so it can be suitable for grinding inner or Outer surface of taper.

The UCG series universal cylindrical grinder has internal grinding apparatus, internal grinding spindle is supported by precise rollbearing.

The worhead spindle, wheelhead spindle, internal grinding spindle, coolent pump, hydrodynamic and hydrostatic oilpump are driven by separatemotors.

Each moving parts of the machine has elctric, hydraulic and mechanic interlock structurethe machine is well designed with pleasing appearance, all control lever are centralized in panel make operating easy.

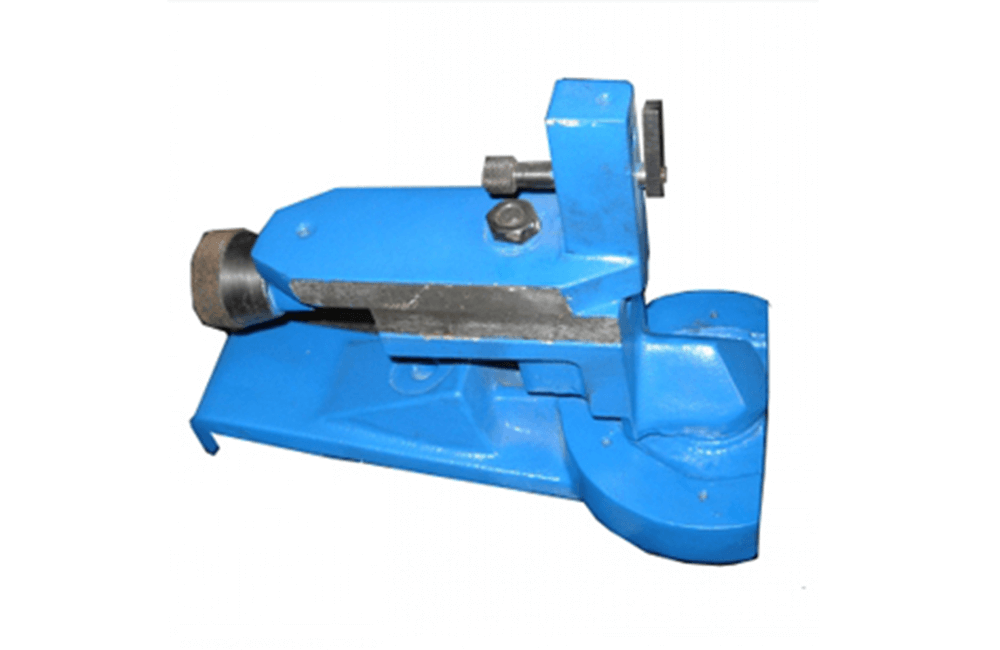

The wheel dresser can be assembled on the worktable surface or on the tailstock.

Configuration is as follows: the bed, the upper and lower work surface, continuously variable headstock, continuously variable switch,tailstock,wheelhead, hydraulic lubrication and hydraulic control system,DELIXI electric, JUCHE transformer ,DELTA converter

Main specifications | Unit | UCG20X800 |

Grinding length (O.D/I.D) | Mm | 800/125 |

Grinding diameter (O.D/I.D) | Mm | φ8~φ200/φ13~φ100 |

Center height | Mm | 135 |

Max. workpiece weight | Kg | 50 |

Work table speed | m/min | 0.1~4 |

Grinding wheel line speed | m/sec | 38 |

Max. amount of movement of worktable | Mm | 950 |

Work table rotating range | ° | |

Cylindrical grinding wheel dimension | Mm | Maxφ400x50xφ203 Minφ280x50xφ203 |

Headstock spindle speed | r/min | 25~380 stepless |

Headstock and tailstock centre tip | Morse | NO.4 |

Total power | Kw | 5.625 |

Overall dimension | Mm | 3000X1600X1500 |

Machine weight | Kg | 3000 |

Machining accuracy | ||

roundness(O.D/I.D) | μm | 1.5/2.5 |

Diameter consistency inside longitudinal section(O.D/I.D) | Μm | 5/8 |

Surface roughness(O.D/I.D) | Μm | Ra0.32/0.63 |

Standard Accessories

Main Accessories | |

coolant tank 1SET | center point 2pcs |

wheel periphery dresser 1 set | leveling wedge 1set |

balancing arbor 1 set | internal grinding rod 1set |

dog plate 1 set | internal grinding attachment 1set |

3-jaw chuck 1set | wheel flange 2sets |

open steady rest 1set | |

Optional Accessories

Wheel balancing stand |

|

Magnetic separator apparatus |

|

Paper filter apparatus |

|

Magnetic separator and paper filter apparatus |

|

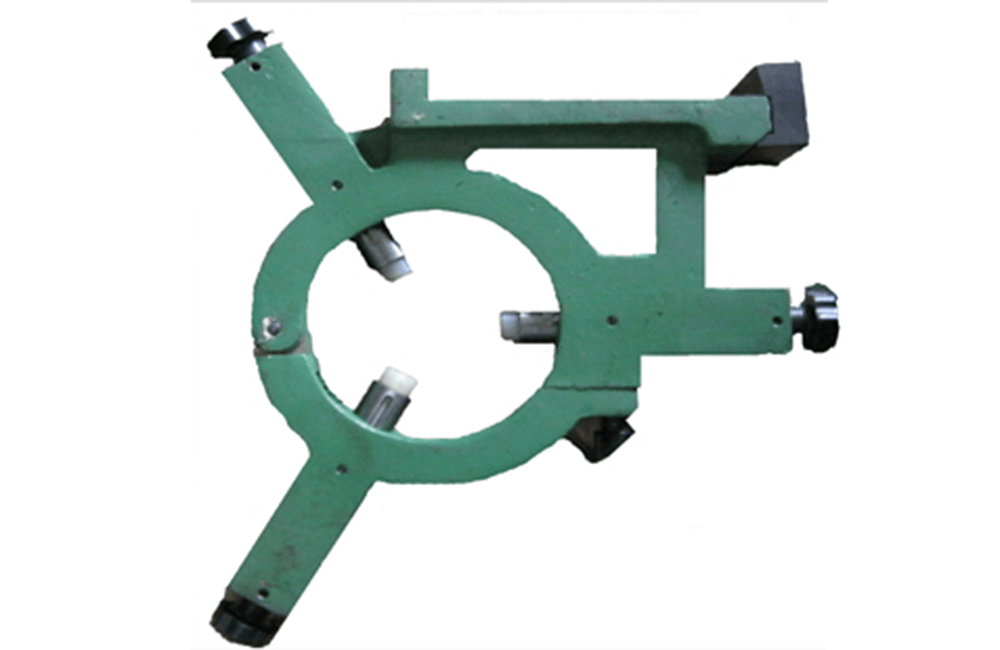

Closed centre rest |

|

Arc dresser |

|