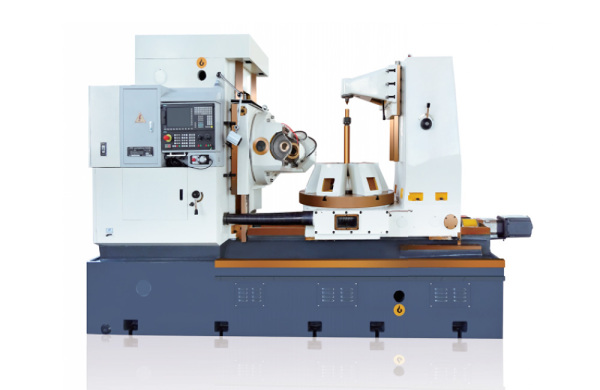

01 | Deep Hole Drilling Machine KT60-1500 Consists of: | Qty. |

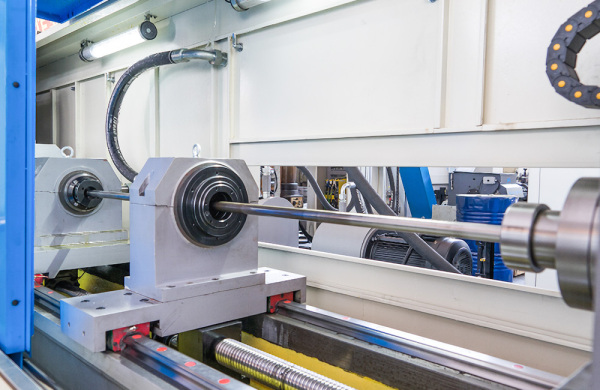

01.01 | Machine Bed | 1 set |

| Cast iron machine bed with heavy rib, treated with annealing for relieves of internal stress. Integrated with ball screw and Line roller guide way for both high stability and precision guiding. |

|

01.02 | Work piece headstock | 1 pcs |

|

Work piece headstock is mounted on the end of machine bed. The spindle driven by A.C. variable frequency motor and 2 kinds of spindle speed. With forced lubrication unit for spindle bearing. Motor power: 15Kw, dual speed Spindle: 1000rpm

|

|

01.03 | Manual 3-jaw Clamping Chuck and flange | 1 set |

|

Mounted to the spindle nose of Work piece headstock. Clamping range: 30-150mm

|

|

01.04 | Work piece support with V block | 1 set |

|

Adjustable supporting height and possitions. Suitable for 30-150mm

|

|

01.05 | Oil Pressure Head and Guide carriage | 2 sets |

|

Mounteded in middle of machine, back and forward to contact work piece by hydraulic cylinder. For rotary work piece, inside with pre-loaded spring bush holder for the bush to contact the work piece. Suitable for drill tube OD 11- 43mm.

|

|

01.06 | Vibration Damper Carriage | 1 set |

|

For reception of damper bush, cast iron housing, mounted Z-axis guide ways. During drilling, the vibration damper carriage will be at best position, and will be dragged back to the original position in reverse movement automatically.

|

|

01.07 | Boring carriage | 1 set |

| In rigid cast iron design, mounted on the guide ways of machine bed. Driven by A.C. servo motor via ball screw. |

|

01.08 | Boring Headstock | 1 set |

|

Mounted on the drill carriage. The spindle is driven by dual-speed servo spindle motor made by MK via belt, with packed long life grease for spindle bearing. Motor power: 22Kw, dual speed Spindle: 1000rpm

|

|

01.09 | Chips outlet | 1 set |

| Fixed to the rear of drill block and introducing chips to chip conveyor. Chip conveyor transports chips to machine outside. |

|

01.10 | Coolant system | 1 set |

01.10.01 | Coolant tank |

|

|

Welded coolant tank of steel plate, including one dirty oil tank and one clean oil tank, Cartridge Filter; stability and easy maintenance; With magnetic plates before inlet of pump, Alarm for coolant level, over pressure/lower pressure and interlock. Total capacity of tank: 2000 L.

|

|

01.10.02 | High pressure pump station | 1 set |

|

Equipped with radial piston pump by Moog, aslo with complete pump drive, pump seat, and regular valves. Delivery rate:120 L/min Pressure: Max. 60Bar Drive power:18.5 Kw

|

|

01.11 | Hydraulic system | 1 |

|

For workpiece clamping. Including all hydraulic elements with pressure sensor for hydraulic circuit.

|

|

01.12 | Electrical equipments and CNC control |

|

01.12.01 | Electrical equipments | 1 set |

|

Independent fully enclosed switch cabinet with air conditioner, wear resistant, flexible cable in wet area. Main electrical elements made by SIEMENS, Schneider,etc. Safety of enclosure: IP54

|

|

01.12.02 | Siemens 828D control system | 1 set |

|

Siemens 828D control system, with standard LCD display: · Operator panel is mounted outside of machine guarding, moveable to right or left, easy operation. · Display in English, no less than 30 alarm messages or disposal of error, I/O location can be vision. · Spindle speed · Spindle capacity (power input ) · Drilling depth · Feed rate · Workpiece counter · Coolant pressure · Etc 1 set Hand wheel is included

|

|

01.13 | Painting | 1 |

|

the machine bed with dark gray, the upper with blue and white gray. (see front picture)

|

|

01.14 | Anchor Bolts , Leveling Pads | 1 set |

01.15 | Documentation | 2 sets |

|

In English/Chinese versions. Including: - Machine layout - Foundation plan - Pneumatics diagram/Hydraulics diagram - Lubrication diagram - Circuit diagram - Transport plan - Operation and maintenance manual

|

|

02 | Oil chiller compress type | 1 set |

|

To maintain stable coolant temperature within the setting range in long shift operation. When the oil temperature reaches the upper limit, the oil cooler start working; the temperature is in the lower limit , the oil cooler stop running. Cooling Capacity: 15 Kw

|

|

03 | Hinge-band Chips conveyor | 1 set |

| Automatically transports the chips to chips trolley outside machine. |

|

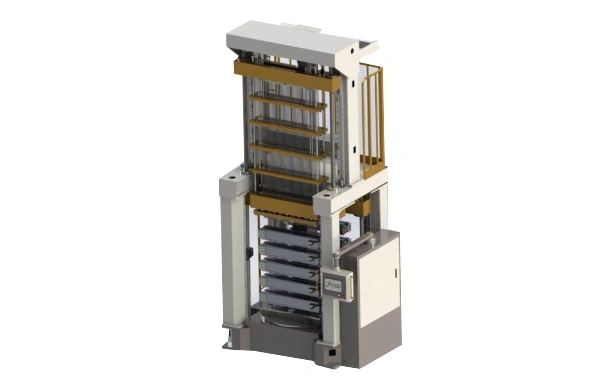

04 | Drum type paper Filter device | 1 set |

|

Deliver dirty oil to filtration device. Hydraulic elements with pressure sensor for hydraulic circuit. For the filtration of coolant with integrated level switches and automatic paper feeding when filtration paper are saturated Filtration accuracy: 30μm Filtration Capacity: ≥300L/min.

|

|

05 | Seaworthy Package, FOB Shanghai Seaport | 1 |

| Incl. Seaworthy packing and transportations to Shanghai seaport |

|

06. | Machine Commissioning and Installation | 1 |

06.01 |

Commissioning and Pre-Acceptance At HTT’s Factory It consists of the machine inspection, checking the functionality of the main components, including the verification of: - geometry accuracy on the headstock - alignment of the boring line components (boring carriage / steady rest / BOZA carriage ). - alignment of the headstock on the work piece bed - accuracy positioning test for boring carriage

|

|

06.02 |

Training Of Customer’s Personnel At HTT’s Factory The customer’s personnel will be trained at HTT’s factory during pre-acceptance test for a period of two weeks. Travel and hotel expense are buyer’s responsibility, local transportation charges are HTT’s responsibility.

|

|

06.03 |

Machine Pre-Acceptance At HTT’s Factory It will consist of the machine inspection, checking the functionality of the main components, include the verification of: - geometry accuracy on the headstock - alignment of the boring line components -alignment of the headstock on the work piece bed -positioning accuracy for boring carriage - test drilling of the test work piece

|

|

06.04 |

Machine Acceptance At Customer’s Factory - Seller will send engineers to buyer’s site for erection, start-up, testing, and commissioning of the machine. - Repeat HTT factory pre-acceptance test -The customer’s personnel can be trained during machine set-up and pre-acceptance.

|