Our machine mainly used in black metals,nonferrous metals and some of nonmetal material parts grinding process.It can rough and fine grinding surface,slot,arc surface and complexity hook face processing.

Our machine have high load-bearing,high precision,high stiffness,long life time,high shock resistance and unfailing performance and many other advantages.

Full enclosed splash guard design.It can well isolate dust and machining spray which produced by grinding processing.Automatically recycling lubrication system.It can recycle reclamation to achieve environmental ,cost saving and other advantages.

Our machine constituted by machine bed,table,saddle,column,head,feeding device, electrical system,operate cabinet,hydraulic system,full enclosed splash guard and other parts.

Machine guide way:

All of our machine guide way use "V"type +flat type .The moving guide way stuck a layer "TURCITE-B",we called it plastics sticking guide way.It can achieve wear-resisting and increase life time of the guide way.And the flat guide way have grinding and scraping process.

Lubrication system:

Automatically recycling lubrication system.It can supply lubricate oil for all of the guide way.

Files:

Operate manual 1 list

CNC system operate manual 1 list

Electrical drawing 1 list

Packing list 1 list

Qualified certification 1 list

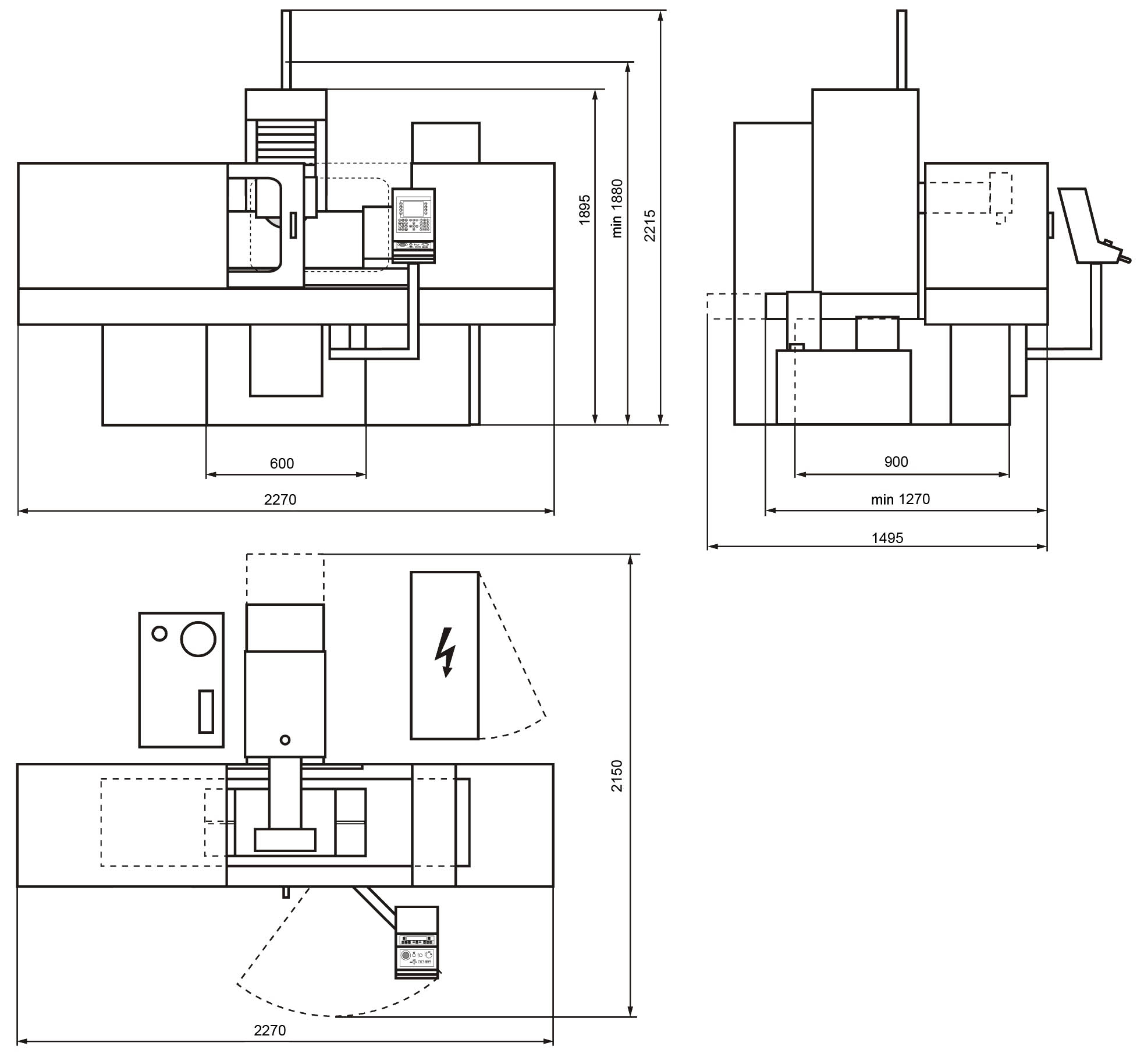

Machine overall dimension and working site requirements:

Machine locating needs room size, contains room size for operating:

Long:4700mm

Wide:3700mm

High: 2000mm

Machine net weight:About 6000kg

We reserve the right to modify the design, specifications, etc. to improve the machine performance without notice.

Parameters | Unit | KGS510CNC-2 |

Grinding length | mm | 1000 |

Grinding width | mm | 500 |

Grinding height | mm | 375 |

Max. table load | kgs | 700 |

X-axis longitudinal movement | ||

Table motion | mm | 10~1100 |

Table speed | m/min | 1~28 |

Power of hydraulic motor | kw | 2.2 |

Table drive mode | Hydraulic drive | |

Table speed control mode | Use potentiometer in the button panel | |

Y-axis vertical movement | ||

Distance table to grinding spindle | mm | 140~600 |

Vertical speed | mm/min | 1~4500 |

Power of servo motor | kw | 1 |

Min down feed | mm | 0.001 |

Vertical feed drive mode | Ball screw drive | |

Vertical feed moving control mode | MPG handwheel or button | |

Z-axis cross movement | ||

Cross motion max | mm | 500 |

Cross speed | mm/min | 1~4500 |

Power of servo motor | kw | 1 |

Min cross feed | mm | 0.001 |

Cross feed drive mode | Ball screw drive | |

Cross feed moving control mode | MPG handwheel or button | |

C-axis grinding spindle | ||

Power of the grinding spindle motor | kw | 11 |

Rotation speed of the grinding spindle | min | 1000~2400 |

Grinding wheel standard | mm | 400×50×127 |

Floor space | mm | 4000×3300 |

Standard accessories:

| 1 | Grinding wheel | 2 | Wheel flange |

3 | Wheel balancing base | 4 | Wheel balancing arbor |

5 | Extractor | 6 | Diamond dresser |

7 | Leveling pad | 8 | Anchor bolt |

9 | Tool box with tools | 10 | Electric chuck(500×1000mm) |

Optional accessories:

| Serial No. | Name of article | Unit price |

1 | Magnetic separator | ¥2600.00 |

2 | Cooling magnetic paper filter | ¥7200.00 |

3 | Suction device | ¥5000.00 |

4 | Diamond roller wheel dresser | ¥20000.00 |

5 | Hydraulic oil cooling device | ¥5000.00 |

Ⅰ. Spindle motor: Use ABB brand from Sweden.

Ⅱ. Spindle bearing: Use NSK brand P4 grade precision ball bearing from Japan.

Ⅲ. Cross and vertical screw: Use P5 grade precision ball screw.

Ⅳ. Main electrical components: Use SIEMENS brand.

Ⅴ. Main hydraulic components: Use brand from TAIWAN.

Ⅵ. Hydraulic motor components:Use brand of WEG which from Brazil.

Ⅶ. Long distance control valve:Use Germany import brand HAWE,it can achieve precision location and control table move speed in the button panel.

Ⅷ. Servo motor (Y and Z axes) components:Use SIEMENS brand.

Ⅸ.CNC control system: Use SIEMENS 808D.